Our Business

HDD Trend

Digitalization, Data Analytics, IoT, Machine Learning, Augmented Reality and more are data-driven facets of the Industry 4.0 era. Data Centers, whether cloud-based and inhouse-based, need to be strategically positioned to cater for this exponential demand for storage of all forms of data.

HDD plays a pivotal role in meeting this colossal data storage requirement.

Our Products

3.5 inches Aluminium Disk

3.5” applications include desktop PC, large video surveillance for intelligent cities initiatives, enterprise systems and building blocks of data centers. To meet the industry push for high platters HDD, thinner disk are required. Resonac HD substrate technology center is developing thinner disks for future adoption.

2.5 inches Glass Disk

2.5 inches glass disks are used in laptops and external mobile hard disks. The current media that we are mass-producing are 1.0 Tb/p. Resonac HD continues to support the huge demand for 2.5 hard disk as the No. 1 independent media manufacturer.

Our Technology

What Is Hard Disk Media?

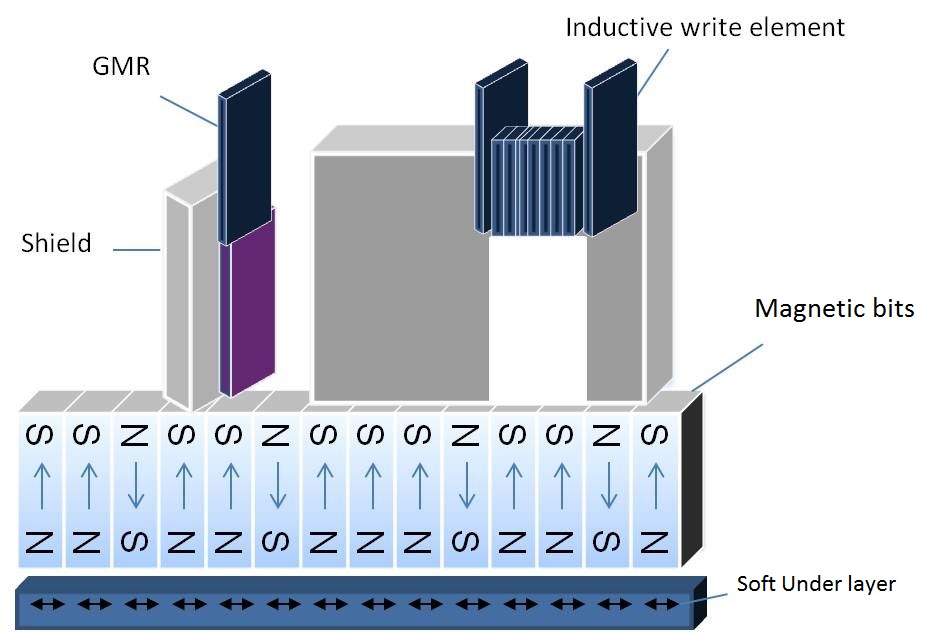

Hard Disk drives are a family of non-volatile memory, which means that they have the ability to retain stored data even when powered off. Hard disk media is one of the primary medium in HDD for memory storage in computers. It is commonly formulated on an aluminium or glass substrate base. Thin films of magnetic alloys are then sputtered on to the substrate and this will contain all the memory in the form of magnetic bits. Just imagine a pizza with everything on it! The orientation of magnetic bits determines the output signals which are then translated into binary signals for the computer to decipher information. Often media development progresses hand in hand with drive channel and head development. Resonac HD is currently in its 9th generation of Perpendicular Magnetic Recording (PMR) media producing media for 14TB (3.5") and 1~2TB (2.5") drives.

Hard disk media come in several sizes, or form factors, depending on their application. Desktop PCs and home consumer electronics use the 3.5" form factor while laptop notebooks , game consoles employ smaller form factors like 2.5" media. Another burgeoning market in need for mass data storage is Near Line HDD in data centers which typically contain all the active and archive data in the cloud computing. Every time you post something on social media it probably gets stored away in a data center archive on a Hard Disk!

Media Manufacturing Process

Storage needs are exponentially growing in an IoT data driven world. It is expected that the data needs explosion will grow with a 30~ 40% annual growth rate. To keep up with this high areal density growth our R&D and manufacturing process are constantly upgrading processes and measurement tools to mass produce latest generation media with increasingly demanding quality.

STEP 1 - Substrates

3.5" aluminium or 2.5" glass substrates are processed.

STEP 2 - Surface Preparation

Substrates are polished to for the purpose of removing substrate level defects and reducing surface roughness for uniform mag crystal growth.

STEP 3 - Wash

All particulate contaminations must be removed and the disk surface must be perfectly clean and dry before entering the vacuum sputtering process.

STEP 4 - Sputter

Magnetic thin film layers are sputtered onto the disk surface. Areal densities for media are primarily determined by this process. Substrates take on magnetic properties after various layers of magnetic alloys are sputtered onto them. A carbon layer finish is applied to make the media more robust and durable.

STEP 5 - Lubrication

A layer of solvent based lubricants are coated over the disk surface to enhance durability and media reliability performance.

STEP 6 - Tape Burnish

An abrasive tape is used to remove any asperities on the disk before testing.

STEP 7 - Testing

Disk is sent for mechanical and parametric testing.

STEP 8 - Packing

All disks that pass testing are then sealed in a vacuum package, ready for shipment to customers.

Media Technology

Shingled Magnetic Recording (SMR)

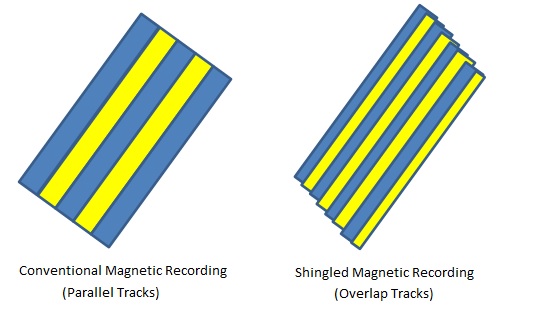

Conventional Magnetic Recording (CMR) consists of tracks written parallel to each other where the minimum track width is constrained by width of the write head. Otherwise there would be adjacent track interference. However in Shingled Magnetic Recording (SMR) the write head is intentionally larger. The larger write head can increase the capability to magnetize the media; thus enhancing the readability, writability and stability of the media. Instead tracks are overlapped on top of each other much like a shingled roof of a house. This, can in turn dramatically increases the areal density of the media, up to 1.3 times kTPI on the same real estate!

Helium Drives

Most HDD are commonly enclosed with air. A novel approach sweeping the industry is to fill the drives with inert gas like Helium. Helium drives reduce oxidation within the drive and media components and reduce aerodynamic drag. This allows for heads to fly lower decreasing head media spacing (HMS) which in turn increases read write capacities. They also save power due to the lower vibration and friction. Media tribology are designed to ensure such lower flying heights are capable.

Upcoming Tech

Next generation media require even smaller and more densely packed magnetic bits. These tiny magnetic layers are highly susceptible to thermal influences and as a result can become highly unstable. One solution is to use high coercivity materials. This makes it difficult for current write heads to induce sufficient magnetic field to cause magnetic bit flipping.

Microwave-Assisted Magnetic Recording

Microwave-Assisted Magnetic Recording (MAMR) makes use of a Spin Torque Oscillator which produces microwave radiation situated on the drive heads. MAMR employs frequencies in the range of 20-40GHz. The microwave energy is highly localized and is able to lower the coercivity of underlying magnetic layers enabling writing.

Heat-Assisted Magnetic Recording

Heat-Assisted Magnetic Recording (HAMR) employs a laser to lower the coercivity of the magnetic layers on the disk. The rapid rise of temperature and ensuing coercivity drop is done in a period of less than a nanosecond. The writer then is able to write the necessary domain alignment. Once the disk cools down it will return to its high coercivity levels to keep its data integrity.